Have any questions?

Get in touch-

Tel : +86 18355532477

-

Whatsapp : +8618355532477

-

Email : 247137166@qq.com

-

Skype : 247137166@qq.com

Have any questions?

Get in touchTel : +86 18355532477

Whatsapp : +8618355532477

Email : 247137166@qq.com

Skype : 247137166@qq.com

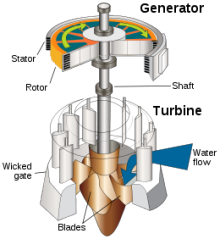

In hydropower stations in different basins, there is widespread abrasion and damage to the flow-through components of turbines, threatening the safe and economic operation of the units.

Payment:

TTProduct origin:

ChinaShipping port:

ShanghaiLead Time:

20 days after receiving the depositHydropower turbine maintenance service

WILA Laser has studied the abrasion damage mechanism through the abrasion test of the material of the flow-passing parts of the turbine; based on the investigation and analysis of the damage causes of the flow-passing parts of the turbine, and through the calculation of fluid dynamics, the influence of hydraulic conditions on the damage of the flow-passing parts of the turbine has been studied and analyzed It also proposes active preventive measures to reduce the degree of abrasion damage of hydraulic turbine units from the aspects of improving hydraulic conditions and optimizing the structure of flow components; through the welding repair test of turbine flow components, spraying tests, etc., research and development of different forms of turbine flow components Abrasion damage repair and protection technology and technology, and analysis of the economics of welding repair and protection technology;

WILA Laser's research revealed the damage and failure mechanism of tungsten carbide (WC) cermet anti-abrasion coatings and clarified the factors affecting the failure of the coatings.

WILA Laser's research revealed the damage and failure mechanism of tungsten carbide (WC) cermet anti-abrasion coatings and clarified the factors affecting the failure of the coatings.

Our technical team has developed 2 welding repair processes, the repair process can achieve micro-deformation, the deformation is less than 0.03mm; developed a surface anti-abrasion coating technology, the coating porosity is less than 0.27%, the anti-wear performance is traditional 1.5 times of the coating and 2 times of the anti-cavitation corrosion performance of the traditional coating.

Different from the traditional activated combustion-supersonic flame spraying (AC-HVAF) repair method, WILA has developed a new nano-micro composite cermet coating, which is more powerful than traditional tungsten carbide coating and full nano-coating. The combined characteristics of high hardness and high toughness significantly improve the abrasion resistance of the flow parts of the turbine.

At the same time, we have developed the anti-abrasion coating strengthening technology for the inner wall of slender and small diameter (minimum Φ48mm) pipes and elbows, which solves the problem of abrasion and leakage of the roof drain pipe that restricts the continuous operation of the unit, and increases its operating life by more than 14 times.

Comparison before and after repair:

click here to leave a message